Wafer Cleaning Equipment Market Size to Surpass USD 18.84 Billion by 2032 at 8.37% CAGR: Research by SNS Insider

The Wafer Cleaning Equipment Market is experiencing significant growth, Owing to Rising Demand for Advanced Electronics and Clean Chip Manufacturing

AUSTIN, TX, UNITED STATES, October 30, 2024 /EINPresswire.com/ -- Market Size & Industry Insights

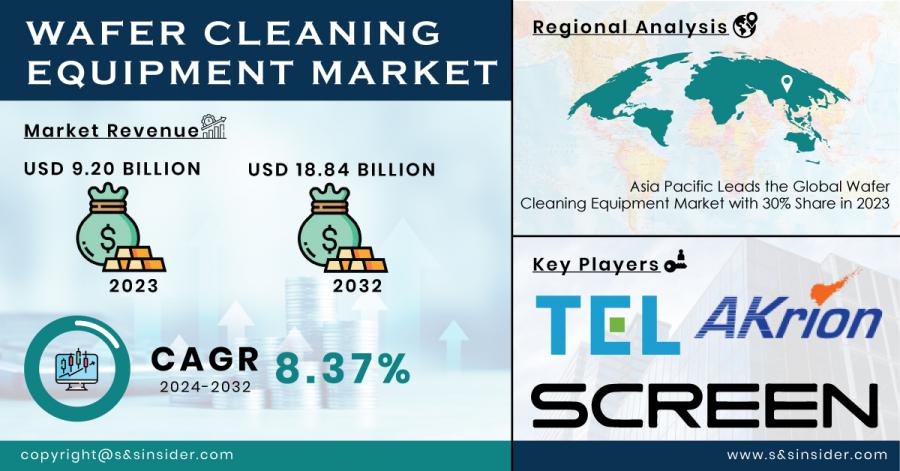

As Per the S&S Insider, “The Wafer Cleaning Equipment Market size was USD 9.20 billion in 2023 and is expected to reach USD 18.84 billion by 2032, growing at a CAGR of 8.37% over the forecast period of 2024-2032.”

Surging Demand for High-Performance Electronics and 5G Drives Growth in Wafer Cleaning Equipment Market

The rapid growth of the wafer-cleaning equipment market is primarily because of the increased demand for electronics and other latest technologies. Consumers are looking more and more for better-performing electronic devices, which puts pressure on manufacturers to use the cleanest process in the production of semiconductor chips. Wafer cleaning equipment plays a crucial role in this process too; it needs to ensure that the most cleaning level for semiconductor chips is achieved to enhance their performance and reliability.

The increased need for quality chips by the increasing population of smart devices and advanced networks, such as 5G, further keeps extending into printed electronics, where new market demands have pushed open new avenues to the latest wafer-cleaning technologies. The processes of making the chips in conventional ways are hard to evolve due to an advance on materials and architectures, thus only demanding special cleaning techniques to get the devices to function at optimum levels. As the wafers scale down in size, and transistor sizes get scaled down, clean processes play a much bigger role. The cleanliness of the wafers ensures not only higher chip performances but also fuelled overall reliability.

Get a Sample Report with Full TOC & Graphs @ https://www.snsinsider.com/sample-request/4371

Leading Market Players are:

-SCREEN Holdings Co. Ltd.

-Tokyo Electron Limited

-Lam Research Corporation

-Applied Materials Inc Inc.

-Shibaura Mechatronics Corporation

-Akrion Technologies

-Modutek.com

-PVA TePLA AG

-Entegris

-ULTRON SYSTEMS INC.

-Veeco Instruments Inc.

-SEMES

-AXUS Technology

-Beijing TSD Semiconductor Equipment Co. Ltd.

-Toho Kasei Co. Ltd.

-Cleaning Technologies Group

-SEMETEK

-AP&S International GmbH

-ITW

-RENA Technologies GmbH

-TDC Co. Ltd.

-Orbray Co. Ltd.

-DAINICHI SHOJI K.K

-Ultra t Equipment Company Inc

Maximizing Efficiency with Mature Node Technologies and Proactive Maintenance Fuels Growth in the Wafer Cleaning Equipment Market

Certain key drivers are transforming and actively driving the wafer-cleaning equipment market. One such is renewed interest in older chip manufacturing equipment has created opportunities for refurbishing and enhancing existing systems. As demand for chips grows the demand for "Smart Phones" and AI-intensifying, manufacturers are increasingly relying on "Mature Node" technologies (wafers sized 200 mm or less). This focus on getting the most efficient use from equipment is in line with the industry requirement for proactive maintenance and parts management, thus considerably improving the OEE in the semiconductor fabrication plants. More critically, as chip manufacturers move from reactive to proactive maintenance strategies, they are finding what was hidden in the operations. Improvement of equipment reliability can increase tool availability by over 15% and thus result in a 10% capacity expansion in fabs without new investments. In turn, this transition not only improves production efficiency but also leads to cleaner wafers, thereby leading to better overall chip performance.

Segment Analysis

By Equipment Type, The Single Wafer Spray System dominates the market, accounting for 35% of the share. It is an essential technology to clean individual wafers so that unmatched accuracy in the cleaning process is achieved. As semiconductor components are getting smaller and more sensitive, the customization of cleaning solutions for each wafer is very crucial.

By Application, MEMS is expected to contribute 30% of the revenue in the market of wafer-cleaning equipment by 2023. These micro-electro-mechanical systems are revolutionizing the tech space, and their keystone is flawlessly clean parts. Since the mechanisms designed are so complex and the roles played so vital-for example, airbags, and self-driving devices slight flaws are catastrophic failures.

Connect with Our Expert for any Queries @ https://www.snsinsider.com/request-analyst/4371

KEY MARKET SEGMENTS:

By Equipment Type

-Single Wafer Spray System

-Single Wafer Cryogenic System

-Batch Immersion Cleaning System

-Batch Spray Cleaning System

-Scrubbers

By Wafer Size

-Less than Equals 150 mm

-200 mm

-300 mm

By Application

-MEMS

-CIS

-Memory

-Logic

-RF Devices

-LED

-Interposer

-Others

Key Regional Development

The Asia Pacific accounts for a 30% share of global consumption value and leads the world. the region leads this field. It is expected that China, Taiwan, South Korea, and Japan would invest substantially to develop their in-house production facilities which reduce the dependence on overseas suppliers. The expanding electronics industry in the Asia Pacific region on account of the huge consumer base and rising demand for smartphones & wearable devices will drive the need for efficient cleaning products to maintain chip quality during manufacturing.

North America is expected to witness a maximum growth rate of 25% in the wafer-cleaning equipment market through 2023. The demand for advanced semiconductor fabrication is helping to drive strong growth in new fab investments and several of the industry's largest players are constructing 12-inch wafer fabs globally; area developers also envisage a healthy installations uptick region-wide. Initiatives like the U.S. CHIPS Act are providing critical funding and incentives in wafer-cleaning technology which serves as a perfect example of how government support helps build an ecosystem that nurtures innovation around the cleaning of wafer developments.

Make an Inquiry Before Buying @ https://www.snsinsider.com/enquiry/4371

Recent Developments

- In July 2023, Tokyo Electron Limited has also just completed its new development building at the Hosaka Office in Yamanashi Prefecture. Complementary to advances in semiconductor manufacturing, this expansion of TEL aims to further enhance its technology development capabilities.

- In January 2023, a new SiCube 4 factory was opened by SCREEN Holdings Co. Ltd. Australian company Molecular Imprints Inc., who specialize in the imprint and etch process technologies for high-resolution semiconductor device patterning, inaugurated its first global development centre Friday solely aimed at leading-edge wafer cleaning tools.

Table of Content - Major Points Analysis

Chapter 1. Introduction

Chapter 2. Executive Summary

Chapter 3. Research Methodology

Chapter 4. Market Dynamics Impact Analysis

Chapter 5. Statistical Insights and Trends Reporting

Chapter 6. Competitive Landscape

Chapter 7. Wafer Cleaning Equipment Market Segmentation, by Equipment Type

Chapter 8. Wafer Cleaning Equipment Market Segmentation, by Wafer Size

Chapter 8. Wafer Cleaning Equipment Market Segmentation, by Application

Chapter 9. Regional Analysis

Chapter 10. Company Profiles

Chapter 11. Use Cases and Best Practices

Chapter 12. Conclusion

Continued…

Purchase Single User PDF of Wafer Cleaning Equipment Market Forecast Report @ https://www.snsinsider.com/checkout/4371

Akash Anand

SNS Insider Pvt. Ltd

+1 415-230-0044

info@snsinsider.com

Distribution channels: Electronics Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release