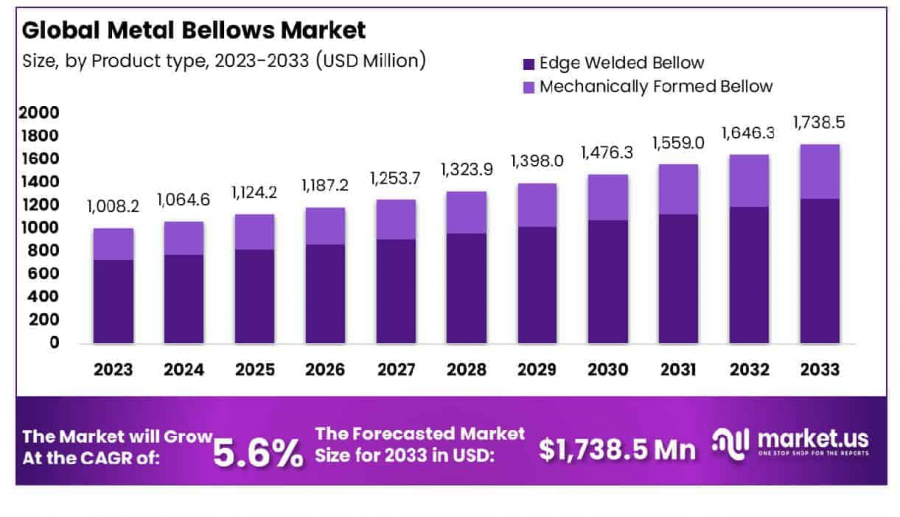

Metal Bellows Market to Hit USD 1,738.5 Million by 2033, Growing at a CAGR of 5.60%

Metal Bellows Market to reach USD 1,738.5 Million by 2033, growing from USD 1,008.2 Million in 2023 at a CAGR of 5.60% during 2024-2033 forecast period.

NEW YORK, NY, UNITED STATES, January 27, 2025 /EINPresswire.com/ -- **Report Overview**

The Global Metal Bellows Market is projected to reach a value of USD 1,738.5 million by 2033, up from USD 1,008.2 million in 2023, reflecting a compound annual growth rate (CAGR) of 5.60% during the forecast period of 2024 to 2033.

Metal bellows are highly engineered, flexible, and durable components designed to absorb movement, accommodate pressure variations, and ensure leak-tight performance in critical applications. Typically constructed from stainless steel, titanium, or other advanced alloys, they feature a corrugated or convoluted structure that enables them to expand, contract, and flex while maintaining their structural integrity. Metal bellows are integral in industries such as aerospace, automotive, healthcare, oil & gas, and semiconductor manufacturing, where precision, reliability, and resilience are essential. They are often employed in sealing, vibration damping, and accommodating thermal expansion within mechanical and industrial systems.

The metal bellows market encompasses the production, distribution, and application of these components across various end-use industries. Valued for their role in ensuring the efficiency and safety of high-performance systems, the market has witnessed significant growth due to increasing adoption in advanced engineering and high-tech sectors. Innovations in material science and manufacturing technologies, such as additive manufacturing and laser welding, have further enhanced the performance and application range of metal bellows, driving their market demand.

Request Your Sample Report Today for In-Depth Insights and Analysis at https://market.us/report/metal-bellows-market/request-sample/

The market's growth is fueled by rising investments in energy infrastructure, growing adoption of automation, and increased focus on reducing environmental impact through leak-proof and efficient systems. The demand for metal bellows is bolstered by stringent industry regulations and the need for precision-engineered components in emerging sectors such as electric vehicles and renewable energy.

Opportunities lie in expanding applications across developing markets, leveraging technological advancements, and catering to the evolving requirements of high-growth industries, positioning metal bellows as a vital component in modern engineering systems.

**Key Takeaways**

~~ The Metal Bellows Market is projected to reach USD 1,738.5 million by 2033, up from USD 1,008.2 million in 2023, growing at a CAGR of 5.60% during 2024–2033.

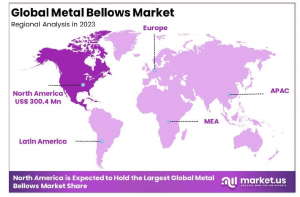

~~ North America leads the market, holding a 29.8% global share, driven by advancements in aerospace and defense industries.

~~ Edge-welded bellows dominate the market, contributing to a significant 72.7% market share, favored for their superior performance in extreme conditions.

~~ Titanium alloys are the leading material choice, accounting for 61.3% of the market, due to their high strength-to-weight ratio and corrosion resistance.

~~ The aerospace sector emerges as a primary end user, representing 25.8% of the market, with growing applications in aircraft systems and satellites.

**Market Segmentation**

In 2023, Edge-Welded Bellows dominated the Metal Bellows Market, capturing a 72.7% share in the product type segment. Their popularity stems from superior durability, precision, and versatility, making them ideal for demanding applications in aerospace, automotive, and semiconductor industries. Constructed by precise edge welding, they offer flexibility and reliability under extreme conditions. In contrast, Mechanically Formed Bellows, while cost-effective, are less durable and better suited for less demanding applications, limiting their market share.

In 2023, the Metal Bellows Market saw Titanium Alloys dominate with a 61.3% share, driven by their high strength, low density, and corrosion resistance, making them ideal for aerospace, automotive, and medical applications. Stainless Steel followed, valued for its durability, corrosion resistance, and affordability, catering to diverse industrial uses. Beryllium Copper, with its high strength, non-magnetic properties, and conductivity, held a niche role in precision-demanding sectors like aerospace and electronics. Nickel Alloys also secured a significant share, prized for their heat resistance and performance in extreme environments.

In 2023, the aerospace sector dominated the Metal Bellows Market's "By End User" segment with a 25.8% share, driven by the demand for precision, reliability, and durability in critical applications like fluid control and thermal expansion compensation. Following aerospace, the automotive sector leveraged metal bellows for exhaust systems, fuel lines, and advanced vehicle technologies, while the oil & gas industry capitalized on their durability in harsh exploration conditions. The electronics and power generation sectors also contributed significantly, fueled by precision requirements and advancements in miniaturization and power systems.

**Key Market Segments**

By Product Type

~~ Edge-Welded

~~ Mechanically formed

By Material Type

~~ Titanium alloys

~~ Stainless steel

~~ Beryllium Copper

~~ Nickel Alloys

By End User

~~ Automotive

~~ Aerospace

~~ Oil & gas

~~ Electronics

~~ Power generation

~~ Medical

"Order the Complete Report Today to Receive Up to 30% Off at https://market.us/purchase-report/?report_id=15837

**Emerging Trends**

~~ Shift Towards Customization: There is an increasing demand for tailored metal bellows to suit specific requirements of industries like aerospace and automotive. Custom-designed bellows help improve system efficiency and safety.

~~ Adoption in Renewable Energy: Metal bellows are finding new applications in the renewable energy sector, especially in wind and solar energy, where they are used in sealing and vibration absorption.

~~ Integration with Smart Technologies: Integration with sensors and smart monitoring systems is becoming more common. This trend enhances the reliability and maintenance cycle of metal bellow systems, reducing downtime.

**Top Use Cases**

~~ Aerospace and Aviation: Metal bellows are widely used in aerospace for fuel systems, actuators, and as expansion joints in various parts. Their ability to handle high pressure and temperature makes them ideal for this sector.

~~ Automotive Applications: In automotive systems, metal bellows are used in exhaust systems and air suspension systems. Their flexibility aids in minimizing vibrations and handling high exhaust temperatures.

~~ Energy Sector: Metal bellows play a critical role in power plants, particularly in steam turbines and other machinery requiring expansion joints to accommodate heat-induced expansion.

**Major Challenges**

~~High Production Costs: Manufacturing metal bellows requires specialized equipment and skilled labor, which increases production costs. This remains a barrier for some small to medium enterprises.

~~Material Fatigue Over Time: Continuous exposure to heat, pressure, and movement can lead to material fatigue, causing wear and tear over time. This limits the lifespan of the bellows.

~~Standardization Issues: The lack of standardization across various industries makes it difficult to manufacture bellows that can be universally applied, leading to inefficiencies and increased costs in production.

**Top Opportunities**

~~Growth in Automotive Industry: As electric and autonomous vehicles become more common, the demand for components like metal bellows in cooling systems, suspension systems, and exhaust systems is expected to grow.

~~Increased Demand in Industrial Automation: With the rise of industrial automation, especially in precision machinery, there is an increasing need for durable and efficient sealing solutions like metal bellows.

~~Technological Advancements in Manufacturing: Innovations in manufacturing processes, such as additive manufacturing (3D printing) and advanced welding techniques, are likely to reduce production costs and improve the performance of metal bellows.

**Regional Analysis**

North America Metal Bellows Market Leads with 29.8% Market Share in 2023

The Metal Bellows market is led by North America, holding the largest share of 29.8% in 2023, valued at USD 300.4 Million. The region's dominance is driven by strong demand from aerospace, automotive, and energy sectors, particularly in the United States. Europe follows with steady growth due to advancements in industrial automation, while Asia Pacific is set to witness the highest growth, fueled by rapid industrialization and infrastructure investments. The Middle East & Africa and Latin America contribute modest shares, with growth tied to energy and manufacturing sector developments.

!! Request Your Sample PDF to Explore the Report Format !!

**Key Players Analysis**

The Global Metal Bellows Market in 2024 is characterized by a highly competitive and fragmented landscape, with key players leveraging innovation, strategic alliances, and geographical expansions to maintain their positions. Companies such as Servometer and MW Industries are known for their precision-engineered bellows, catering to high-performance applications across aerospace and defense sectors. EnPro Industries Inc and EagleBurgmann KE stand out with diversified portfolios and strong global distribution networks, focusing on sealing and vibration isolation solutions.

Meggitt Plc and USA Bellows, Inc emphasize customizations to meet specific client requirements, targeting the expanding energy and automotive markets. Meanwhile, KSM Corporation and Technoflex Corporation focus on product reliability for critical applications in industrial machinery. European players like BOA Holding GmbH and Freudenberg Group emphasize sustainable manufacturing practices. Smith Group and Pebiflex capitalize on technological advancements, making the market highly dynamic with robust growth potential driven by demand across industries.

Top Key Players in the Market

~~ Servometer

~~ EnPro Industries Inc

~~ EagleBurgmann KE

~~ Meggitt Plc

~~ USA Bellows, Inc

~~ KSM Corporation

~~ Technoflex Corporation

~~ BOA Holding GmbH

~~ Freudenberg Group

~~ MW Industries

~~ Smith Group

~~ Pebiflex

**Conclusion**

The Global Metal Bellows Market is poised for robust growth, driven by increasing adoption across aerospace, automotive, and renewable energy sectors. With a projected CAGR of 5.60% from 2024 to 2033, advancements in manufacturing technologies and rising demand for precision-engineered components will fuel market expansion. Opportunities in industrial automation and energy infrastructure, coupled with challenges like high production costs, will shape the competitive landscape. North America and Asia Pacific are expected to lead in market share and growth, respectively, underscoring the strategic importance of innovation and regional investments in driving future success.

Lawrence John

Prudour

+91 91308 55334

email us here

Visit us on social media:

Facebook

LinkedIn

Distribution channels: Manufacturing

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release