MOSES LAKE – Group14 Technologies, a Woodinville-based battery materials company, is preparing to begin production at its massive factory complex in Moses Lake later this year, marking a major milestone in its mission to transform the battery industry.

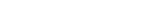

The 1 million-square-foot campus, which has been under development for several years, will begin with a single production module, according to Group14 co-founder and CEO Rick Luebbe. A second module is expected to come online by the end of 2025 or early 2026.

"We're already permitted for six modules," Luebbe said. "That's about 12,000 tons of production."

Group14 specializes in manufacturing a silicon-based anode powder designed to replace traditional graphite in lithium-ion batteries, offering the potential for longer-lasting, more efficient, and compact batteries. The company aims to play a central role in the rapidly growing electric vehicle market.

Founded in 2015, Group14 has attracted substantial financial support, including a $614 million Series C funding round in 2022 and $300 million in grants from the U.S. Department of Energy through the 2021 infrastructure law.

Of the company’s 420 employees, approximately 200 are based in Moses Lake and 180 in the Seattle area. Group14 also maintains teams in Germany and South Korea. While the Moses Lake site gears up for production, the company’s headquarters in Woodinville will remain focused on research and development. Group14 will also keep its office space in Seattle’s South Lake Union neighborhood.

Moses Lake has emerged as a hub for battery technology, drawing companies thanks to low-cost power and a skilled industrial workforce. In April, Sila Nanotechnologies reached the commissioning stage of its own facility in the area. Meanwhile, OneD Battery Sciences, which opened facilities in Moses Lake last summer, has since closed those sites.

The region also hosts REC Silicon, a Norway-based polysilicon producer that creates silane gas—a key component in emerging battery technologies. In December, REC announced it would cease polysilicon production in Moses Lake but continue to maintain its silane production equipment, potentially easing competition for silane among battery manufacturers.

One of Group14’s federal grants supports the construction of its own silane plant in Moses Lake. Luebbe confirmed those plans remain intact, despite REC’s idle silane facility.

"We're still keeping an eye on REC and what their plans are for their idle silane plant, but the default plan is for us to have independent silane," Luebbe said. "Outside of Asia, the only active silane plant in the world right now is in Butte. ... Even if you add in Moses Lake, that's now one company controlling all non-Asian silane, and that's problematic."

A company spokesperson said there is currently no timeline for when Group14’s silane plant will open.